Concrete agreements and good monitoring are essential to increase the quality level. The perfect tool: AQL.

OPEN ENROLLMENT, also IN-COMPANY

Today’s consumer is critical; good quality is a must. No matter how beautiful the design is, in the end, fabric flaws, crooked seams, broken accessories, stains, falling off buttons and other ‘defects’ from the manufacturing process can cause the product not to catch on after all, or the number of returns and complaints to rise too much. Reputational damage and customer loss are likely. Moreover, it can affect durability and occasionally the product is even dangerous for the user concerned. Efficient handling of quality reports and issues requires good agreements on the quality level, checks and communication. A handy tool is AQL, a globally accepted standard, with statistical backgrounds. Learn everything you need to know about this standard on AQL and quality control in general, in order to manage your suppliers, agents and internal involved parties more skillfully!

Expected outcomes for participants after the session:

- have relevant knowledge of the AQL system and eliminate misunderstandings

- knowing which knobs can be turned within the AQL

- ability to make communication internally and with producers more effective

- ability to identify minor, major and critical product-defects

- understand how commerce relates to quality control.

What you will work on, among other things:

- improve the current system of control and communication

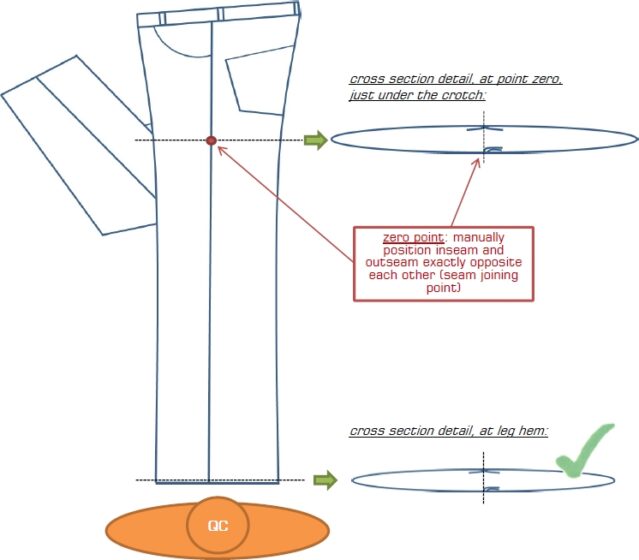

- recognising defects

- improve insight in AQL-reports

- communicate effectively with your producers and agents.

This you will do with skilled coaching ofChris Koeleman. Chris is an senior trainer with a profound practical experience in quality assurance at several fashion brands and with AQM Quality Control, Testing and Auditing. And fully versed in quality assurance, quality manuals, testing, inspections, garment production and effective communication about quality management with the manufacturer. In this training of one morning:

- the theory, how does AQL work precisely

- exercise minor, major and critical defects

- what do you need to arrange for an external QC-party

- discussing specific questions from your own practice.